Aerospace High-Precision CNC Machining | CNC, 5-Axis & Laser Solutions

With the rapid development of the global economy and continuous technological progress, the aerospace industry has become an important component of national strategic emerging industries. As a modern means of transportation, aircraft demand extremely high standards of safety, reliability, and comfort. Therefore, the manufacturing accuracy and quality of aerospace components have become key factors in evaluating aircraft performance.

Table of Contents

1. Applications of High-Precision Machining in Aerospace Manufacturing

High-precision machining technology plays a crucial role in aerospace component manufacturing. Its applications can be illustrated in the following aspects:

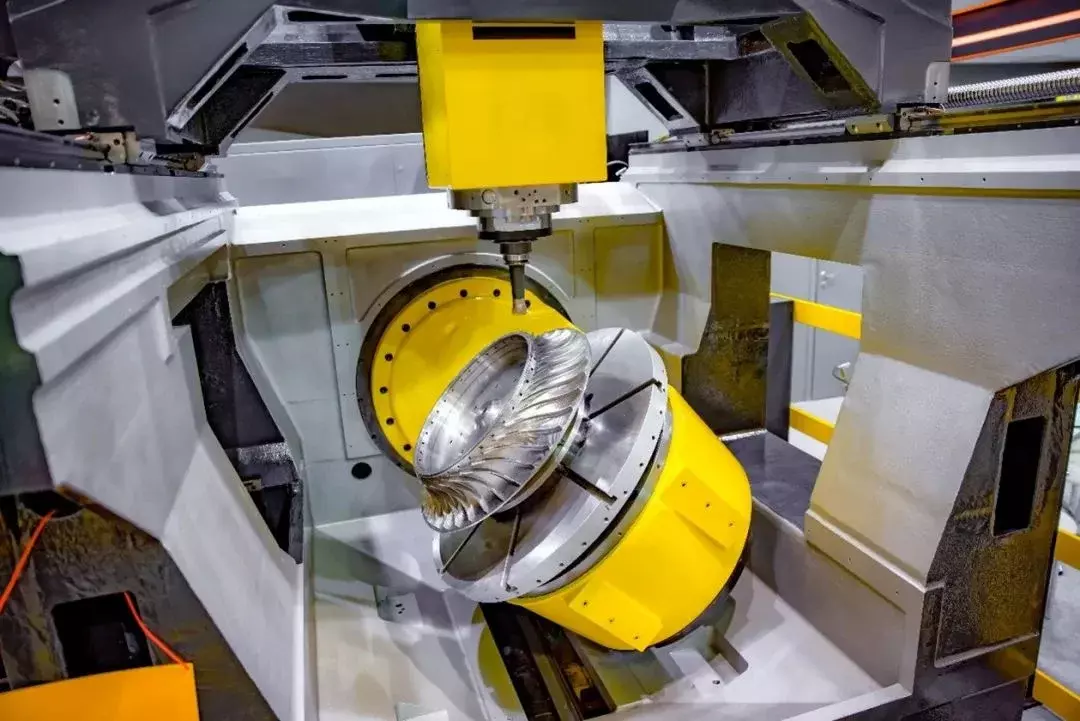

Enhancing machining accuracy

High-precision machining technology significantly improves the dimensional accuracy of aerospace components, reducing tolerance ranges and thereby enhancing overall aircraft performance. For example, in the machining of key components such as engine blades and turbine disks, high-precision techniques ensure that the dimensions, shapes, and surface quality of the parts meet stringent design requirements.

Improving surface quality

By adopting advanced machining methods such as precision grinding and ultra-precision machining, high-precision technology effectively enhances surface quality. Components with superior surface finishes can reduce friction, minimize wear, and extend service life, ultimately improving the safety and reliability of aircraft.

Reducing production costs

High-precision machining technology reduces production costs by optimizing processes and improving efficiency. At the same time, it lowers rework rates and scrap rates, further boosting manufacturing productivity and economic benefits.

Meeting the demands of complex structures

Aerospace components often feature complex geometries. High-precision machining technology is capable of meeting these complex structural requirements. For instance, when machining difficult-to-process materials such as composites or titanium alloys, high-precision methods ensure machining quality and enhance product performance.