How High-Automation & Robotics Are Transforming CNC Manufacturing

In the heart of modern manufacturing facilities, a quiet revolution is transformingthe way we produce precision components. The integration of robotics, artificialintelligence, and advanced automation systems with Computer Numerical Control (CNC) machining is not just an incremental improvement-it's a paradigm shift that's redefining the boundaries of what's possible in manufacturing.

As we stand at the threshold of industry 4.0 , the convergence of CNC technology with intelligent automation systems is creating unprecedented opportunities for manufacturers worldwide. From collaborative robots working alongside human operators to fully autonomous "lights-out" manufacturing facilities operating 24/7without human intervention, the future of precision manufacturing is being written today.

1. Why Automation Matters in Modern CNC Machining

Automation is becoming the backbone of competitive CNC machining for three major reasons: labor cost, consistency, and scalability.

Labor shortages: Across the U.S. and Europe, skilled machinists are increasingly difficult to hire. In contrast, automated systems can operate 24/7 with minimal supervision.

Higher stability: Robots eliminate variability caused by manual loading or manual inspection. This leads to more consistent dimensions, smoother surface finishes, and fewer reworks.

Scalable output: Automated CNC milling and CNC lathes cells allow shops to increase volume without adding proportional headcount.

Recent industry reports show that automation can reduce operating labor costs by 30–50% and improve equipment utilization by up to 60% when implemented correctly. This directly impacts the overall cost structure for CNC import buyers looking to optimize budgets without compromising quality.

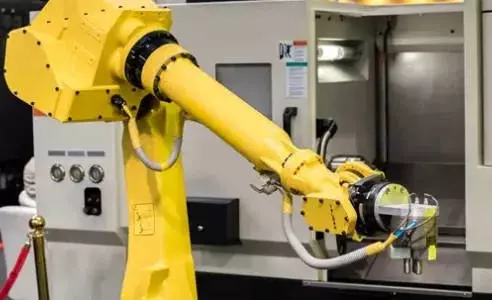

2. Robotics Integration: From Cobots to Full Automatic Cells

Robotics—especially collaborative robots (cobots)—are now widely used in CNC facilities. Their roles have expanded far beyond simple material handling.

Key applications include:

Automatic loading & unloading

Robots can pick raw aluminum stock, steel bars, or machined components and place them precisely into CNC milling machines or CNC lathes. This reduces idle time between cycles.

In-process and final inspection

Equipped with vision systems and AI-based measurement tools, robots can detect dimensional deviations, scratches, burrs, and surface defects.

Parts transfer & palletization

Robots ensure a smooth transition between machining, deburring, cleaning, and packaging stations—ensuring traceability and minimizing handling errors.

According to data from leading industrial automation suppliers, cobot deployment in CNC machining has grown by 20% annually over the past five years. This trend is expected to rise as programming becomes easier and as shops aim for more flexible production systems.

3. Lights-Out Machining: The Future Is Already Here

One of the most significant shifts in modern CNC machining is the rise of lights-out manufacturing—running machines unmanned during night shifts or weekends.

Thanks to robotics, advanced workholding, and AI monitoring systems, lights-out machining is no longer limited to giant corporations. Even medium-sized CNC precision shops can now achieve:

Overnight production without operators

Machines continue cutting aluminum, brass, plastic, or steel parts long after staff have gone home.

Real-time AI monitoring

Sensors track vibration, tool wear, temperature, coolant levels, and spindle load to prevent accidents.

Automatic tool and job changeovers

ATCs, robotic feeders, and software scheduling help machines run multiple jobs autonomously.

Shops running lights-out operations report 20–40% higher output per machine—substantial efficiency improvements with almost zero added labor cost.

4. How AI is Enhancing CNC Precision and Operational Efficiency

AI is playing an increasingly important role in CNC machining—often behind the scenes. While not visible in the final product, its impact is significant.

Examples of AI-driven improvements:

Predictive maintenance

AI analyzes spindle load, tool wear patterns, and cycle-time deviations to predict when maintenance is needed—reducing unexpected downtime by up to 50%.

Smart toolpath optimization

Algorithms automatically adjust feeds and speeds to reduce machining time while maintaining accuracy.

Quality and defect detection

AI vision systems catch micro-defects earlier, especially in high-precision aluminum parts.

Production planning & traceability

AI scheduling ensures every CNC milling and CNC lathe machine runs at optimal utilization.

For buyers of CNC import components, AI-enhanced production means better repeatability, lower scrap rates, and greater supply chain reliability.

5. Automation Brings Real Cost Advantages to CNC Import Buyers

For companies sourcing CNC parts globally, automation offers tangible benefits:

Lower production cost

By minimizing human labor and maximizing machine uptime, automated CNC machining reduces per-unit cost—especially for medium-to-high volumes.

Better lead time consistency

Robots don’t take holidays, sick leave, or breaks. This ensures stable delivery schedules, even during peak seasons.

Tighter tolerances & higher accuracy

AI monitoring and robot-assisted workflows reduce process variability, improving CNC precision for complex geometries.

Enhanced transparency

Automated data logging improves traceability, allowing customers to track machining parameters, batch records, and QC reports.

For industries like EV, telecom, medical devices, automation has become a key selection factor when choosing CNC import suppliers.

6. What Highly Automated CNC Shops Look Like Today

Modern high-automation factories combine multiple technologies into one integrated system:

Robotic arms feeding CNC milling and lathe machines

RFID or QR-code material tracking

Cobots doing secondary processes (deburring, cleaning, polishing)

Vision systems for automatic inspection

AI dashboards monitoring machine health

AGVs or AMRs transporting parts

Smart fixtures enabling faster setups

Automatic pallet changers for long-run jobs

These elements work together to form a stable, efficient, and predictable production environment.

In short, automation upgrades CNC machining from a labor-driven process into a data-driven and AI-supported production ecosystem.

7. Automation Is Reshaping the Future of CNC Manufacturing

High automation, AI, and robotics are no longer optional—they are becoming essential for CNC manufacturers serving global markets. For European and North American buyers, partnering with automated CNC shops means better quality, faster lead times, more predictable costs, and stronger supply chain resilience.

As CNC machining moves further into digitalization and robotics integration, the gap between automated and non-automated suppliers will only continue to widen. Companies that adapt early will gain long-term competitive advantages in precision, efficiency, and scalability