Capabilities

Max part size: up to 800mm × 500mm

Tolerance: ±0.01mm

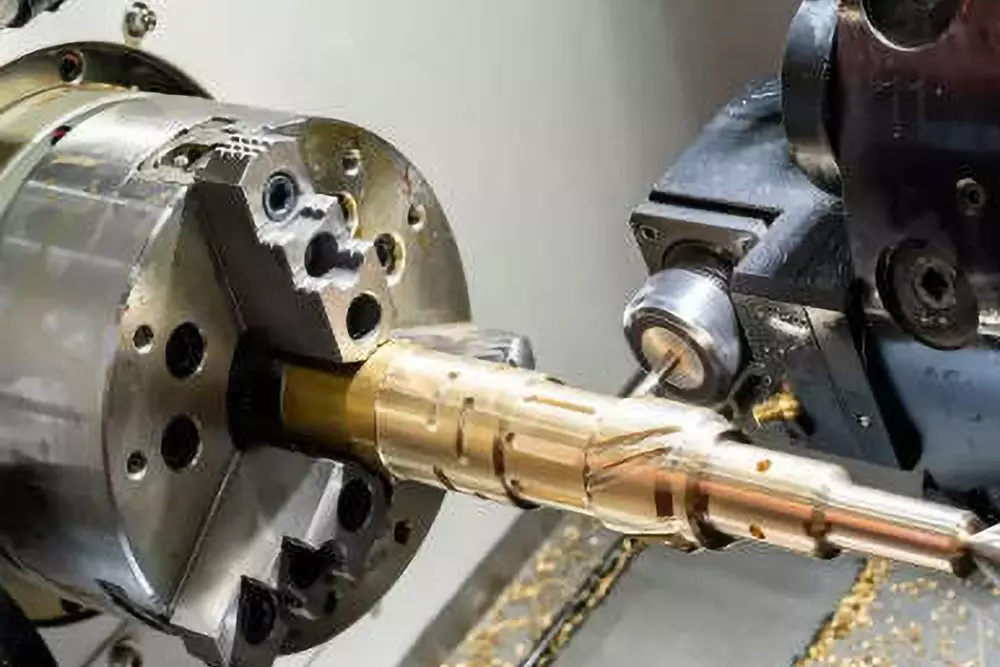

Materials: Aluminum, Stainless Steel, Copper, Brass, Titanium, Plastics

Batch range: From one-off prototypes to mass production

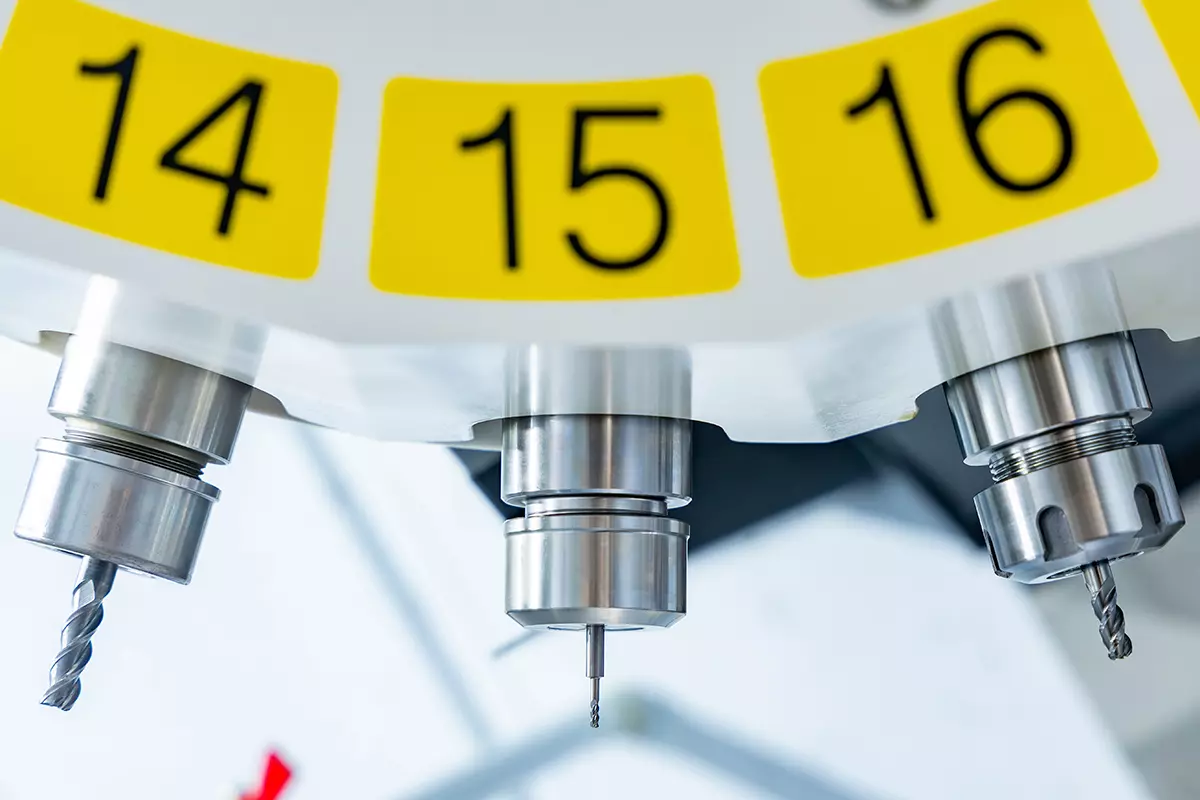

3/4/5-Axis Comparison

3-Axis CNC Milling

Key Features: Moves along X, Y, Z axes

Best for: Flat surfaces, slots, basic holes

Advantages: Cost-effective, fast for standard parts

4-Axis CNC Milling

Key Features: Adds rotation around X-axis (A-axis)

Best for: Multi-side parts, cylindrical cuts

Advantages: Fewer setups, improved accuracy

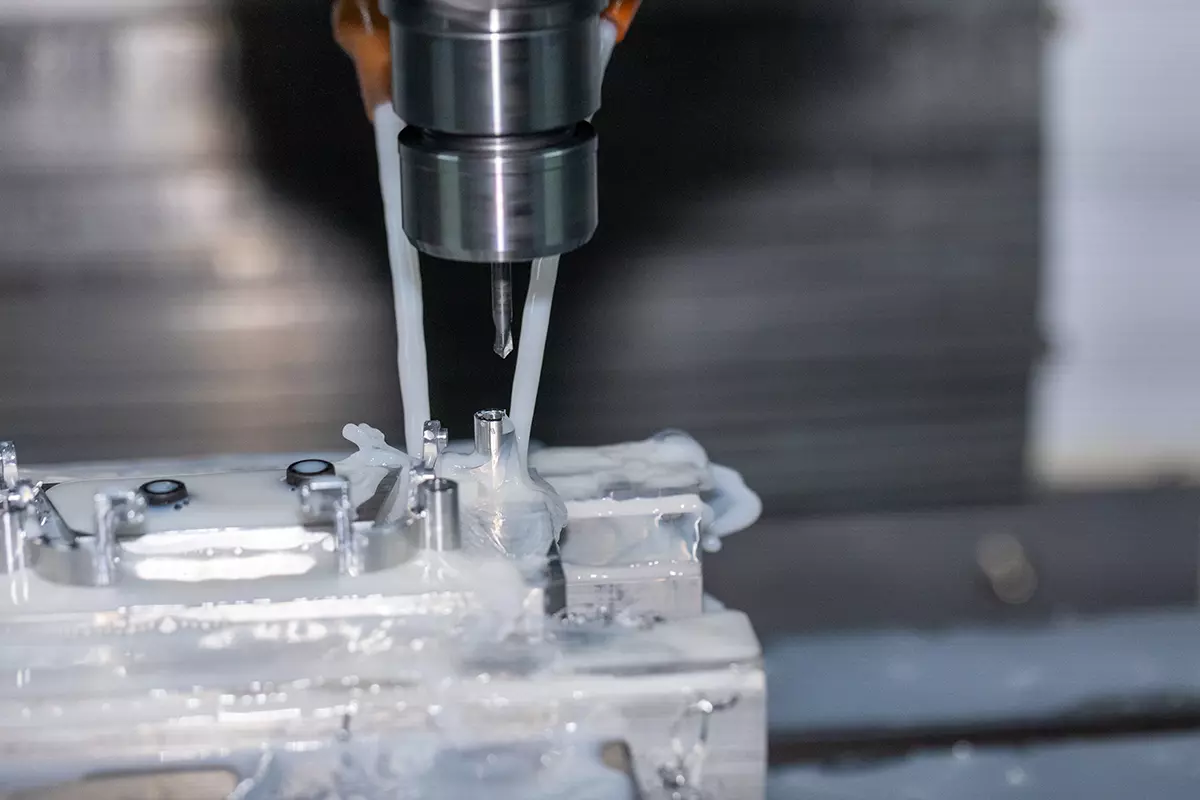

5-Axis CNC Milling

Key Features: Adds rotation around X and Y axes (A & B axes)

Best for: Complex geometries, curved surfaces, precision parts

Advantages: One-step machining, fewer setups, ultimate precision

Our CNC milling solutions serve a wide range of industries:

Consumer Electronics – Device housings, heat sinks, brackets

Automotive – EV components, engine parts

Medical Devices – Surgical tools, precision connectors

Telecommunications – 5G housings, cooling systems

Why Choose Our CNC Milling

High Precision – Accuracy up to ±0.01mm

Flexible Production – From prototype to volume

Superior Finish – Smooth surfaces, ready for assembly

Fast Turnaround – Typical lead time 3–5 days

Quality Assurance

Strict in-process inspection and final quality checks

Advanced CMM and measuring tools

ISO 9001 certified quality system

Value-added Services

Rapid prototyping for product development

Wide range of surface finishing (anodizing, polishing, plating, painting)

Small-batch to large-scale manufacturing transition