Face Milling Explained:Definition, Applications, Tools, Process

Face milling is indispensable in the metalworking industry, which is undergoing significant transformation. Without face milling, the complexity of machining processes would be unimaginable. This technique achieves precision and surface quality improvements by generating flat surfaces to complete reference surfaces. Furthermore, the production of many rotating components remains incomplete without face milling. Clearly, the importance of face milling cannot be underestimated.

Table of Contents

1. What Is Face Milling?

Face milling is a type of CNC milling process, meaning it involves using cutting tools to remove material from a workpiece. However, unlike conventional milling, this process requires positioning the cutting tool so that its rotational axis (or tool axis) is perpendicular to the workpiece. Note how the multi-tooth cutting tool is positioned facing downward toward the top of the workpiece. As the workpiece passes through the cutting tool, material is removed by rotating the cutting tool counterclockwise.

2. Applications of Face Milling

1. Creating Flat Surfaces

Face milling is most commonly used to produce flat, level surfaces on workpieces. This step often serves as the foundation for further machining operations, providing a precise reference surface that ensures overall part quality and accurate assembly fit.

2. Surface Preparation for Subsequent Machining

Before operations such as pocket milling, drilling, or profile cutting, face milling smooths and levels the workpiece’s top surface. This preparation reduces tool wear in later steps and improves dimensional accuracy.

3. Improving Surface Finish

Face milling produces finer surface finishes compared to many other machining methods. The use of overlapping cutting paths and multiple inserts helps minimize post-processing such as grinding or polishing, making it ideal for parts that require high-quality finishes.

4. Squaring Up Workpieces

Face milling can also square the sides of blocks or plates, ensuring workpieces are accurate and repeatable. This improves alignment in fixtures and prevents dimensional errors in subsequent machining.

5. Industry Applications

Automotive: Surfacing cylinder heads, engine blocks, and base plates.

Aerospace: Preparing large aluminum and titanium components with tight tolerances.

Mold and Die Making: Producing flat, precise surfaces on mold bases and inserts.

General Manufacturing: Leveling steel, aluminum, or plastic stock before machining complex geometries.

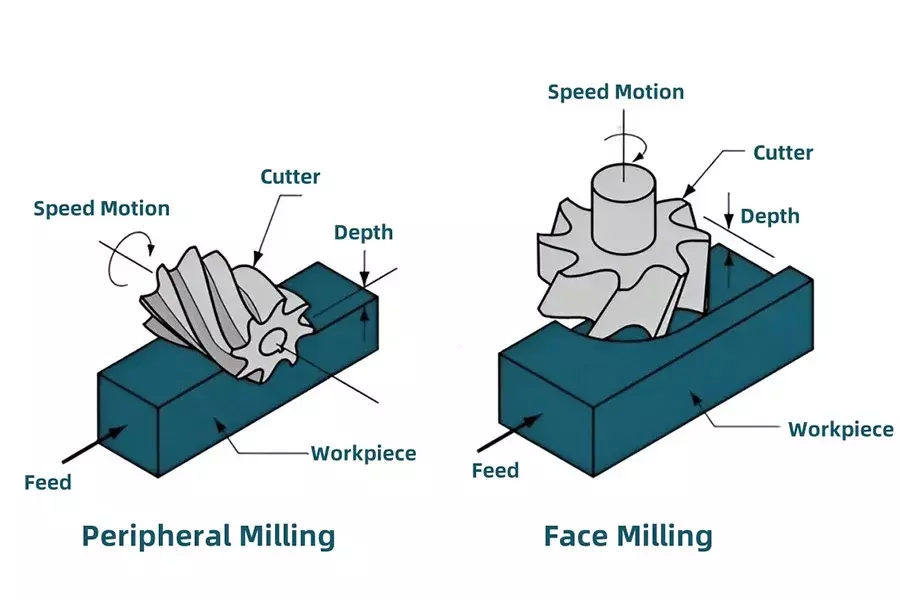

3. Face Milling vs. Peripheral Milling: What’s the Difference?

Face milling and peripheral milling are two primary types of milling operations. Their operational modes are very similar, but they differ in setup and suitability for manufacturing features. For example, in peripheral milling, the cutting tool is positioned parallel to the workpiece, as shown below. The unique configuration of peripheral milling ensures the tool’s flank grinds away the top surface of the workpiece. Consequently, peripheral milling can efficiently remove large volumes of material from the workpiece. In contrast, face milling uses the tool tip to remove small amounts of material, making it more suitable for applications requiring fine surface finishes.